Here at dow plastic s technical service department we recently set out to fill this gap by compiling some of the knowledge we ve gained from our.

Plastic sheet extrusion problems.

The variables range from the quality of the die and materials to temperatures and pressures.

Monday january 21st 2013.

This process starts by feeding plastic material pellets granules flakes or powders from a.

Dozens of questions flooded in from attendees and he could only respond to a handful during the allotted time for the live q a.

2014 s s gadekar et al 2014 defects in extrusion process and their impact on product quality j g khan1 r s dalu2 and s s gadekar1 corresponding author.

In order to solve extrusion problems you have to understand the process.

This webinar demonstrated how simulation was used to help understand and solve some extrusion and coextrusion problems.

Polymer extrusion problems defects 1.

Troubleshooting information for general extrusion problems and for some specific applications such as film has been widely available but the same is unfortunately not true for sheet extrusion.

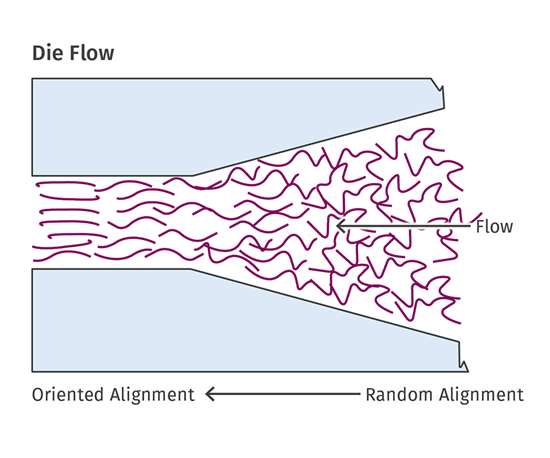

Extruded polymer remembers its.

It is recommended for the reader new to extrusion to take classes covering the material characteristics of plastics typical features of extrusion machinery instrumentation and operating controls the inner workings of extruders and screw and die.

But what he didn t have during a recent webinar on the key principles of extrusion hosted by plasticstoday was time.

Extrusion problems defects 2.

The table below gives a general overview of the guide summarizing the typical causes and likely solutions to 12 common quality problems in sheet processing.

Common problems of plastic extrusion.

Plastics extrusion is a high volume manufacturing process in which raw plastic is melted and formed into a continuous profile.

You ve got questions about extrusion and allan griff has the answers.

Some of the variables are based on equipment others on operating conditions.

The more complicated issues involve problems with sheet appearance or aesthetics.

A good understanding of the extrusion process is necessary to solve extrusion problems efficiently.

To ensure successful extrusion manufacturing every parameter must be identified controlled and monitored.

Many extrusion operations however rely primarily on on the job training though this is often the least effective and in some respects the most expensive method.